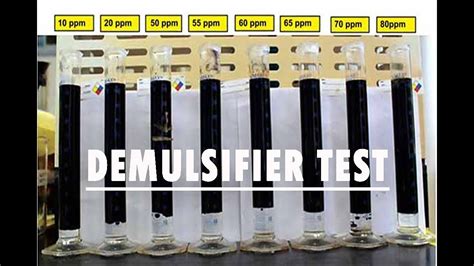

oil field bottle test|oil demulsifier field testing : purchasing Saudi Aramco R&D Center developed an improved, more rigorous, bottle-testing procedure and used it on a stable water-in-oil emulsion to rank the performance of eight demulsifiers. Lojas Boyzinhos - Loja de Roupas para Bebê e Enxoval de B.

{plog:ftitle_list}

22 de jan. de 2021 · Elected president of the Métis Nation B.C., Clara Morin Dal Col, has been suspended from her position amid escalating tension within its leadership. Métis National Council calls suspension a .

After the bottle tests, two or three promising demulsifiers are selected for field testing. During the field trials, the screened chemicals should be tested at various concentrations, operating temperatures, and settling times and tested for clarity of separated water and, most .

how to test springs on tattoo machine

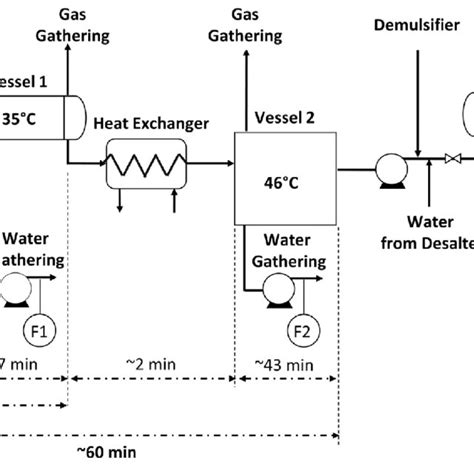

Saudi Aramco R&D Center developed an improved, more rigorous, bottle-testing procedure and used it on a stable water-in-oil emulsion to rank the performance of eight demulsifiers. The bottle test is a simple assessment of the rate of emulsion separation by visual observation of the separated volume of water with time. The bottle test does not take .This bottle-test methodology was benchmarked against field trial results performed in oil processing plants. The field trials were also improved to avoid the accumulation effect of .

oil demulsifier field testing

Bruce has the bottle testing expertise to help you optimize your demulsifier program for effective oil/water separation. Stepan also offers a diverse range of chemistries to address the .This course is designed for oilfield professionals who need to conduct oilfield demulsifier bottle tests using a pre-designed procedure. Field emulsion evaluation using centrifugation method .

This bottle-test methodology was benchmarked against field trial results performed in oil processing plants. The field trials were also improved to avoid the accumulation effect of. The bottle test is a recommended procedure to analyze a combination of essential parameters such as the demulsifier dosage, residence time, heat, degree of agitation to generate the. Solving oilfield emulsion problems is often addressed with the field bottle test. This widely used and informative method uses fresh samples and readily generates a number of . Chemical demulsifiers are routinely added in the oil field to effectively resolve water-in-crude-oil emulsions. As used in the common bottle test, demulsifiers, in effect, probe .

demulsifier bottle testing

In this work, a new approach to bottle test and field trial was described which improved significantly the selection and dosage of the demulsifier. The bottle test was optimized by measuring an accurate mass of demulsifier. . 3.2 Bottle test procedure. Arab Medium crude oil emulsions were sampled from the production header of the production .

Choose a needle-tip squeeze bottle for your most precise dispensing applications. Height does not include the needle.. Opaque black bottles are good for light-sensitive contents.. Use 27-gauge and 25-gauge needles with water-thin liquids; 23- and 20-gauge needles with light oils; and 18- and 16-gauge needles with heavy oils and adhesives.. For technical drawings and 3-D .

The test bottle was first filled with 50 mL cation brine and then dosed with a pre-calculated amount of inhibitor. After adding 50 mL anion brine, the test bottle was quickly capped, sealed and shaken to mix thoroughly. Before placing the bottle into a preheated oven at 160 °F, ∼15 mL brine was withdrawn using a needle syringe for chemical .

The bottle test is the traditional method used to assess oil emulsion stability [2, 12, 13, 15]. The bottle test is a sim-ple assessment of the rate of emulsion separation by visual observation of the separated volume of water with time. The bottle test does not take into consideration the “live” production stream pressure or the geometric . Firstly, the residence time (0.025s) for the brine solution to travel through the capillary cell after mixing is very short compared to the long residence times (2 h, 22 h) used for the standard bottle test (Graham and Sorbie, 1997). The longer residence time of bottle test would promotes growth of crystals at later stages.Calculate oil and water residence times. Calculate amount of agitation. Run ratio tests to verify bottle test variables. Finalize bottle test procedures. Sample bottle test procedures. Discussions on bottle test results. Solids in grind-out. Treating window. BS in top cut. BS in mixed cut. White foam or un-natural looking oil quality. Extremely .in the oil field. The corrosion history of the oilfield system in general . test specimens consistent with the field construction material has provided comparisons between laboratory test data and effects experienced in the field. A comprehensive analysis of the well or production

smart tutorDemulsifier Lab Bottle Test Petroleumin this video you learn how to seperate oil and water from crude oilsubsribe for more videoand if you have no. 3.3.2 Dynostat Test for Sour Field Testing. After purging each test bottle with CO 2, specified amount of sodium sulfide is weighed and immediately placed in each test bottle. Required volume of crude oil mix prepared as above (4.1.2.2 A) is added to each bottle and kept under CO 2 blanketing.

Emulsion separation index test. The emulsion separation index (ESI) test provides a measure of the stability of the emulsion. This emulsion bottle test is a quantitative method for demulsifier testing and involves the following procedure. The crude oil emulsion sample is tested as soon as possible after it is received in the lab.V Bottle Test The ‘Bottle Test’ is an application test to check performance of demulsifiers on a small scale Bottle testing can determine several things , e.g. Performance of incumbent product Ratio of demulsifier Amount of emulsified water Demulsified oil quality Demulsified water quality

Demulsifier Bottle Test - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document discusses the objective, design, and methodology of conducting a demulsifier bottle test. It aims to break water-in-oil emulsions and analyze parameters like water cut, water drop, interface, water clarity, and salt content. The document outlines designing the bottle test . Oil analysis is the process of chemically analyzing an oil sample to determine lubricant and engine or component condition. . so it won’t pull contaminants off the bottom of the oil pan. Pump the plunger until the bottle is 3/4 full. Sometimes it’s impossible to draw an oil sample from the top, so you’ll have to pull the sample straight . Microscopy of emulsions with 30% oil cut at 25 . To see the Bottle test in action, check out the attached video! By investing in quality testing and analysis, producers can improve the efficiency .

There are three methods carried out, starting from the thermal stability test, static bottle test, and dynamic scale loop test. . The solubility of common oil field scales formed and how their .

in-oil emulsions in the crude oil from Mabruk oil field, Libya. This was achieved by conducting a series of industrial standard Bottle-Test’s on the crude oil emulsions from Mabruk oil field. Mabruk oil field is located in Libya's Sirte basin. Mabruk’s crude oil has a moderate emulsion tendency easily treated by injecting anWater-in-crude oil emulsions are formed during the oil exploration process. The stability of emulsions varies depending on the weak or strong emulsions, the age, and the source type of the emulsions [1].Secondary and advanced oil recovery processes also promote the formation of tight, stable emulsions because of the pipeline’s turbulent and shearing flow during exploration .• The color and condition of the oil can be observed as well. This is especially true for tank/sump mounted sight glass used as level gages. In-line sight glasses are less helpful in this area. Darkening oil and cloudy oil suggest problems with oxidation, wrong oil, or contamina-tion. Foam in the sight glass is always a concern. We found the best olive oil dispensers for storing, pouring, and spraying. Our list offers oil dispenser bottles made from stainless steel, fine porcelain, glass, and copper — including classic .

Learn how to test for H2S for crude oil samples in the field by using a modified ASTM 5705 test. Once H2S levels are determined, Q2 Technologies can help in .

The preceding bottle tests demonstrated the potential for severe MIC in stagnant water bodies within the infrastructure of the investigated oil field. However, the pipelines that transport multiphasic fluids (e.g., from offshore production wells) usually experience high flow and, as a result, wall shear stresses, which greatly increase the . The demulsification test was performed for the synthesized demulsifier through the standard bottle test method using water-in-oil field emulsion. The results indicate that the demulsifier has an excellent dehydration rate and can achieve a demulsification efficiency of 85% within 10 minutes at a concentration of 200 ppm and 100% efficiency in .1.1.1 This standard describes field test methods for estimating bacterial populations commonly found in oil and gas systems. Although these techniques have been successful in the oil field, they are not the only methods that are used. It is not the intent of this standard to exclude additional techniques that can be proved useful.

In this work, a new approach to bottle test and field trial was described which improved significantly the selection and dosage of the demulsifier. The bottle test was optimized by measuring an accurate mass of demulsifier. . , respectively. 3.2 Bottle test procedure Arab Medium crude oil emulsions were sampled from the production header of . The field system survey is a critical first step in performing a regular emulsion breaker bottle test right the first time. By going through this procedure, the emulsion breaker bottle testing .Download scientific diagram | Two 100-mL centrifuge tubes used for bottle testing. from publication: A new method to select demulsifiers and optimize dosage at wet crude oil separation facilities .evaluating film persistent inhibitors for oil field applications [5]. The wheel test is described as versatile because the procedure may be adjusted to test a variety of inhibitors and may be performed on various types of test specimen. Unfortunately, the low level of reproducibility of the test results offsets the advantages of its versatility.

WEB28 de abr. de 2020 · Os alunos têm acesso ao AVA no link http://ava.femass.edu.br/, disponibilizado, gratuitamente, no Portal da prefeitura www.macae.rj.gov.br/femass. .

oil field bottle test|oil demulsifier field testing